Lockheed Martin's 750th HIMARS: Why This Production Milestone is a Glimpse Into the Future

The Real Weapon Isn't the Rocket. It's the Factory.

We tend to get fixated on the shiny object, don’t we? The sleek fighter jet, the powerful rocket, the single piece of technology that captures our imagination. But we often miss the real story, the seismic shift happening just behind the curtain. When I saw the report, Lockheed Martin hits 750th HIMARS delivery, and learned they had also doubled annual production from 48 to 96, I had one of those moments. This isn't a story about a single weapon system. It's a story about the rebirth of American industrial might and the dawn of a new era where precision is no longer a boutique capability, but a mass-produced commodity.

When I first read that they had ramped up the Camden, Arkansas facility two months ahead of schedule, I honestly just sat back in my chair, a little stunned. In a world so often defined by delays, budget overruns, and supply chain nightmares, that single data point speaks volumes. It’s a testament to what happens when focus, funding, and human ingenuity align. Imagine the scene on that factory floor: not a dusty, clanking relic of the past, but a humming, streamlined ecosystem where new tooling and empowered workers are shaving weeks and months off production timelines. This is the kind of breakthrough that reminds me why I got into this field in the first place.

This is about more than just meeting demand. It’s about building a muscle. The ability to scale complex manufacturing isn't just flipping a switch; it's a deeply intricate dance of logistics, engineering, and workforce training. What Lockheed Martin is demonstrating isn't just how to build more HIMARS; they're creating a playbook for how to build anything complex at speed. And that playbook, that capability, is arguably more important than the launcher itself.

The Model T of Modern Deterrence

Let’s reframe this for a second. For decades, the most advanced military hardware was treated like a bespoke suit—meticulously crafted, incredibly expensive, and produced in limited numbers. The HIMARS system, a highly mobile launcher for guided rockets and missiles, was a game-changer in its own right. It’s a system designed for what the military calls “long-range precision fires”—in simpler terms, it’s the ability to reach out from hundreds of miles away and hit a specific target with surgical accuracy. It’s the difference between a sledgehammer and a scalpel, but a scalpel that can operate from the next state over.

What we're witnessing now is the "Model T moment" for this kind of technology. Before Henry Ford, the automobile was a handcrafted luxury for the rich. Ford’s revolution wasn’t just building a car; it was building the assembly line. He made the automobile accessible, reliable, and standardized, and in doing so, he didn't just change transportation—he changed the world. Lockheed Martin, backed by a predictable stream of government contracts, is doing something analogous for 21st-century defense. They are turning a high-tech, precision instrument into a platform that can be produced at a scale that was once unthinkable.

The speed of this is just staggering—it means the gap between a strategic need and a fielded solution is closing faster than we can even comprehend. This isn't just about bolting metal together. It’s about hardening the entire supply chain, empowering the workforce, and embracing what site director Adam Bailey called the reality that “speed matters… on the factory floor.” This shift from artisanal production to a high-volume, high-tech assembly line is a paradigm shift. So, what happens to global security when the ability to deliver a precise effect anywhere, anytime, is no longer a rare and precious resource but a foundational capability for an entire network of allied nations? Does the very existence of this scaled-up industrial power change the calculus for potential aggressors before a single shot is ever fired?

A Networked Future, Built on a Shared Blueprint

The most profound implication here isn't just for the U.S. military. It’s for the entire global network of alliances. With 14 partner nations already operating HIMARS, this production surge creates a powerful network effect. When allies share the same equipment, they can also share training, logistics, and operational planning. It creates a seamless fabric of interoperability that is, in itself, a powerful form of deterrence. It’s like everyone suddenly agreeing to use the same operating system—the potential for collaboration and shared innovation explodes.

Of course, with this incredible power comes an immense responsibility. The industrialization of precision warfare demands an equal, if not greater, investment in the wisdom, ethics, and restraint required to wield it. Having a powerful tool is one thing; knowing when and how to use it is another entirely. This new reality forces us to ask tougher questions about the rules of engagement and the future of conflict.

But the core of this story remains one of incredible, forward-looking optimism. It’s a story of American innovation not just in the lab, but on the factory floor. It’s proof that we can still build big, complex, important things—and we can do it faster and better than ever before. This isn't just about defense; it's a signal for every other industry. The principles of streamlining processes, empowering workers, and investing in the supply chain are universal. This is the blueprint.

The Real Weapon is the Assembly Line

Ultimately, the 750th HIMARS launcher is just a symbol. The real story, the one that should give us all a sense of profound possibility, is the system that built it. The true strategic asset isn't the single piece of hardware, but the resilient, scalable, and innovative industrial base that can design, build, and deliver it at speed. That capability—the power to turn an idea into a reality, not once, but a hundred times over—is the ultimate deterrent and the most potent engine of our future.

Related Articles

California's FIRO Water Project: What It Is and Why You Shouldn't Believe the Hype

Better Late Than Never, I Guess So, gather ‘round, because I’ve just read a press release that’s bei...

Ivory Coast: World Cup Dreams and Border Concerns

Ghana, Nigeria, and Ivory Coast: Africa's World Cup Dream Team? Okay, folks, buckle up, because I'm...

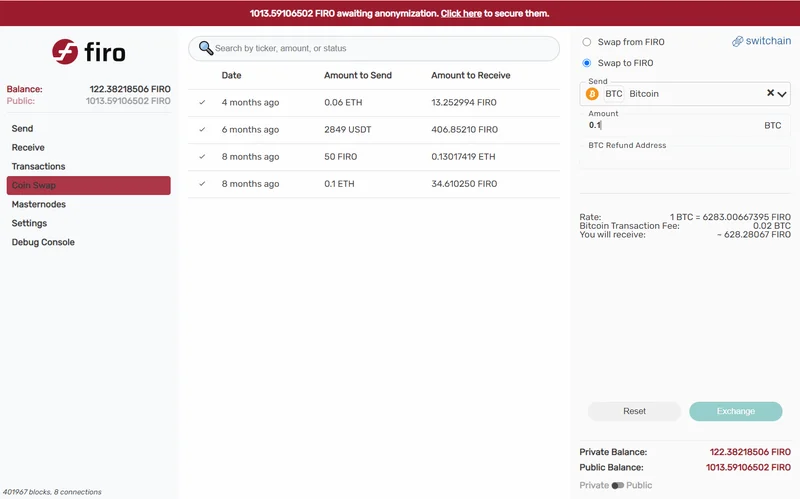

Firo's Chennai Launch: Restaurant and Cocktails vs. Reservoir Management?

Generated Title: FIRO: California's Water Fix or Just Another Tech Bro Fantasy? Is Smarter Really Be...

Ergo: Can a Chair Really Fix Your Posture?

The Frido Glide Ergo Chair: A Design That Listens to Your Body? I've always believed that the best d...

The Aster Name is a Mess: A breakdown of the flower, the crypto, and the weird-ass movies

Forget Crypto, My New Investment is a Six-Inch Weed Called 'Snow Flurry' So, I’m scrolling through m...

SpaceX launch today: What's the point?

SpaceX's "Record Launch Cadence"? More Like a Monoculture of Mediocrity So, another SpaceX launch. Y...